|

Our Products

|

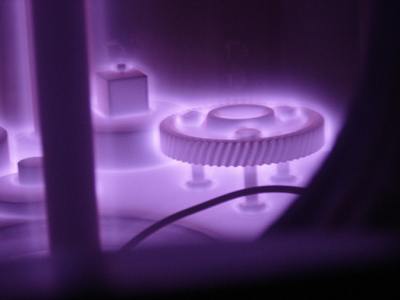

Pulsed Plasma Ion Nitriding Technology

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MILMAN THIN FILM SYSTEMS PVT. LTD. 322 A 1,2 & 3 , Vishwachaya Industry Road PIRANGUT, PUNE 412115, Maharashtra, INDIA. Mobile: +91 98814 70865 Phone: +91 788085401 / 7888085404 / 7888085405 |

| Copyright © 2021 Milman Thin Film Systems Pvt. Ltd. | Design by Livetek Software Consulting Services |