|

Our Products

|

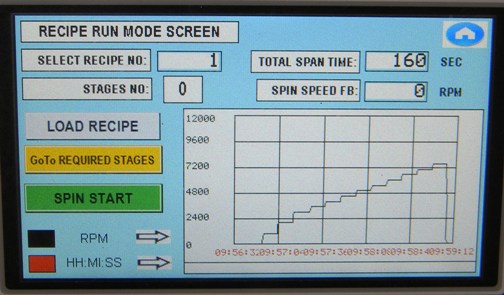

SERIES 4000A

SPIN COATING UNIT model 4000 A series from MILMAN is a multistage HMI interfaced spin coater .This is a special and precise design to coat thin films of photoresists, sol-gels, paints, polymides, anti-reflective and other liquids on substrate sizes upto 4" x 4" upto 6"×6". Available Speed range is 0-12000 RPM. The unit is fully programmable and user friendly. The spin coating unit is provided with Top plate assembly, motor assembly, safety interlocks, vacuum chuck and wide range of accessories.

TYPICAL PROCESS RESPONSE GRAPH

GENERAL FEATURES:

SPEED:

PROGRAMMABILITY:

CYCLE RUN:

INTERLOCKS:

ACCESSORIES ( OPTIONAL ):

|

|

MILMAN THIN FILM SYSTEMS PVT. LTD. 322 A 1,2 & 3 , Vishwachaya Industry Road PIRANGUT, PUNE 412115, Maharashtra, INDIA. Mobile: +91 98814 70865 Phone: +91 788085401 / 7888085404 / 7888085405 |

| Copyright © 2021 Milman Thin Film Systems Pvt. Ltd. | Design by Livetek Software Consulting Services |

.jpg)