|

Our Products

|

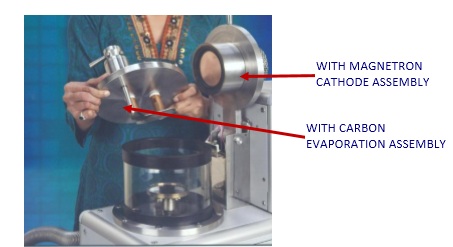

SEM Coater

“SEMCOATER”is compact portable table top sputtering equipment specifically designed for deposition of continuous and uniform conducting layer of metals such as Au, Pt etc. on specimen surfaces for scanning electron microscopy applications. Equipment incorporates 57 mm diameter Air cooled magnetron capable of coating 8 stubs of 0.5 inch diameter in one cycle. Main features of the equipment are fast pump down and rapid specimen processing coupled with simple but safe operation with excellent reproducibility. The system can be operated through HMI-PLC based control located on the front panel[1]. High vacuum option including Turbo-molecular pump is also available for deposition of coatings such as Cr, Al etc.

Carbon film evaporation assembly compatible with this coater is offered as option for X-ray micro-analysis applications. MAIN FEATURES

CARBON EVAPORATION ASSEMBLY

The assembly can be directly adapted to the MILMAN ‘SEMCOATER’.

MAIN FEATURES:

|

|

MILMAN THIN FILM SYSTEMS PVT. LTD. 322 A 1,2 & 3 , Vishwachaya Industry Road PIRANGUT, PUNE 412115, Maharashtra, INDIA. Mobile: +91 98814 70865 Phone: +91 788085401 / 7888085404 / 7888085405 |

| Copyright © 2021 Milman Thin Film Systems Pvt. Ltd. | Design by Livetek Software Consulting Services |

.jpg)

.jpg)

.JPG)

.jpg)